English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

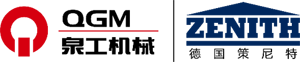

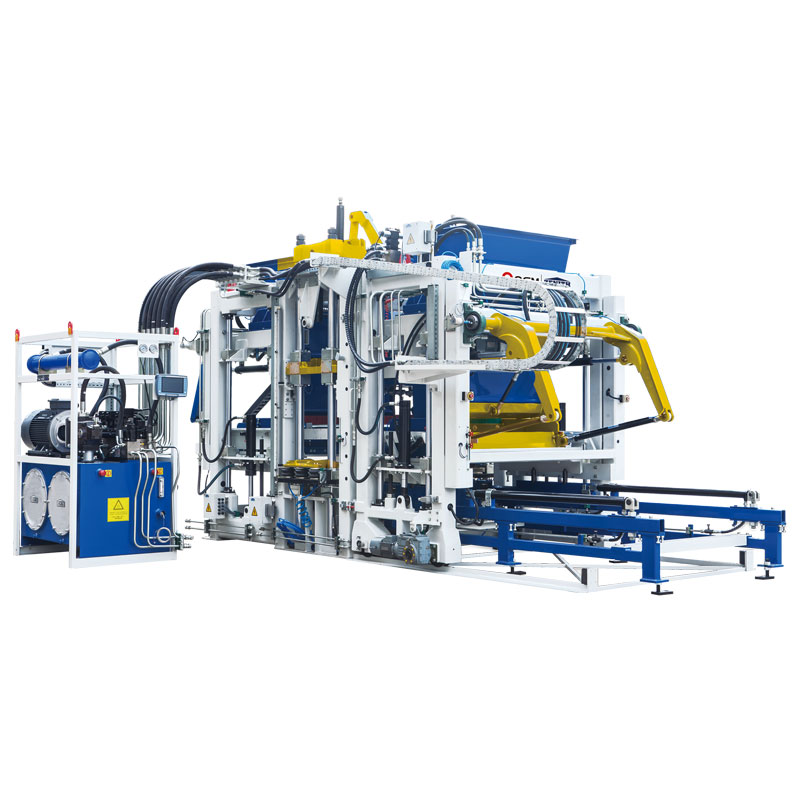

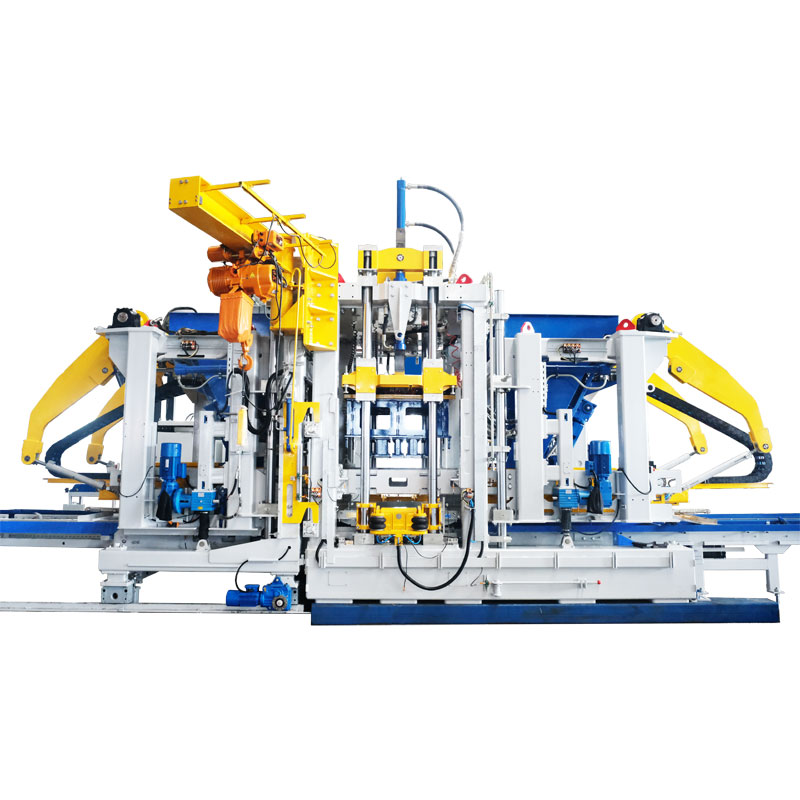

ZN1000C Mashiinka Block la taaban karo

Soo dir weydiin

Tilmaamaha Farsamada ugu Muhiimsan

1) Xakamaynta tignoolajiyada beddelka ee soo noqnoqda

Iska yaree mootada bilawga hadda iyo xakamaynta shaqada bilawga jilicsan, dheeree nolosha matoorka. Oscillator-ka ugu weyn ee ZN1000C Mashiinka Block Concrete wuxuu qaataa heegan hooseeya iyo hawlgal joogto ah, kaas oo hagaajinaya xawaaraha hawlgalka iyo tayada badeecada. Yaree qalabka farsamada iyo burburka matoorka, dheereeya nolosha matoorka iyo makaanikada. Badbaadiyaha soo noqnoqda ayaa badbaadinaya qiyaastii 20% -40% awood ka badan beddeliyaha dhaqameed.

2) Nidaamka xakamaynta Siemens PLC ee Jarmalka, Siemens touchscreen, Jarmalka

Hawlgalka fudud, saamiga hooseeya ee fashilka, ZN1000C Mashiinka Block Concrete Block ee ku socda xasilloonida iyo kalsoonida sare. Isticmaal tignoolajiyada intarneedka warshadaha ee ugu horumarsan, garwaaqso dhibka-toogashada fog & dayactirka. PLC iyo muraayadda taabashada waxay wada isticmaalaan PROFINET internet-ka, oo ku habboon ogaanshaha nidaamka iyo ballaarinta WEB. Si joogto ah u gaar dhibaatada ogaanshaha iyo nidaamka digniinta, ku habboon dayactirka mishiinka iyo cilad-bixinta. PLC waxay ku socotaa xogta ilaalinta joogtada ah.

3) Nidaamka Gariir

Miiska gariirku wuxuu ka kooban yahay miis firfircoon iyo miis taagan. Marka gariirku bilaabmo, miis firfircooni wuu gariiraa, miis fadhiya wuu taagan yahay. Qaab dhismeedka waxaa loogu talagalay in lagu hubiyo baaxadda miiska gariirka, si loo hubiyo tayada sare ee alaabta la taaban karo. Miis gariir la isticmaalayo HARDOX birta. Habka gariir: iyadoo la isticmaalayo gariir miiska gariir + caaryada sare gariirka; Rakibaadda matoorka qalabaynta gariirrada iyo qalabka qaboojinta hawada.

4) Nidaamka Quudinta

Baabuurtu waxay isticmaalaan matoorada SEW, kuwaas oo maamula laba ulood oo isku dhafan. Qaabka quudinta, saxanka hoose iyo daabka isku dhafka ah ayaa laga sameeyay birta HARDOX oo heer sare ah, meesha saxanka hoose waa la hagaajin karaa. Nidaamka quudinta ayaa leh qalab daboolaya si looga hortago daadinta. Albaabka albaabka laga soo daayo waxaa maamula matoorka SEW.

5) Saldhig Haydarooliga

Matoorada Haydarooliga iyo valves-ka Haydarooliga waxay qaataan noocyo caalami ah. Tube waxay isticmaashaa "Xiriirka Flange, rakibida iyo dayactirka habboon nidaamka danab, badbaadinta tamarta.

Xogta Farsamada

| Max. Aagga Samaynta | 1,100*820mm |

| Dhererka alaabta dhammaatay | 20-300mm |

| Wareegga qaabaynta | 15-25s |

| Xoog xiiso leh | 80KN |

| Cabbirka suufka | 1,200*870*(12-45)mm |

| Samaynta lambarka block | 390*190*190mm(10 baloog/caaryo) |

| Miis gariir | 2*7.5KW |

| Gariir sare | 2*0.55KW |

| Nidaamka xakamaynta korantada | SIEMENS |

| Wadarta miisaanka | 42.25KW |

| Cabirka Mashiinka | 12T |

Awood-soo-saarka

| Nooca xannibaadda | Wax soo saarka | ZN1000C Block Mashiinka Samaynta |

240*115*53mm |

Tirada baloogyada la sameeyay (block/ caaryada) | 50 |

| Mitir cubic / saac (m3 / saac) | 13-18 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 1005-1400 | |

| Tirada lebenka (blocks/ m3) | 683 | |

390*190*190mm |

Tirada baloogyada la sameeyay (block/ caaryada) | 9 |

| Mitir cubic / saac (m3 / saac) | 22.8-30.4 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 182.5-243.3 | |

| Tirada lebenka (blocks/ m3) | 71 | |

400*400*80mm |

Tirada baloogyada la sameeyay (block/ caaryada) | 3 |

| Mitir cubic / saac (m3 / saac) | 69.1-86.4 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 553-691.2 | |

| Tirada lebenka (blocks/ m3) | 432-540 | |

245*185*75mm |

Tirada baloogyada la sameeyay (block/ caaryada) | 15 |

| Mitir cubic / saac (m3 / saac) | 97.5-121.5 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 777.6-972 | |

| Tirada lebenka (blocks/ m3) | 2160-2700 | |

250*250*60mm |

Tirada baloogyada la sameeyay (block/ caaryada) | 8 |

| Mitir cubic / saac (m3 / saac) | 72-90 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 576-720 | |

| Tirada lebenka (blocks/ m3) | 1152-1440 | |

225*112.5*60 |

Tirada baloogyada la sameeyay (block/ caaryada) | 25 |

| Mitir cubic / saac (m3 / saac) | 91.1-113.9 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 728.9-911.2 | |

| Tirada lebenka (blocks/ m3) | 3600-4500 | |

200*100*60 |

Tirada baloogyada la sameeyay (block/ caaryada) | 36 |

| Mitir cubic / saac (m3 / saac) | 103.7-129.6 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 829.4-1036.8 | |

| Tirada lebenka (blocks/ m3) | 5184-6480 | |

200*200*60 |

Tirada baloogyada la sameeyay (block/ caaryada) | 4 |

| Mitir cubic / saac (m3 / saac) | 72-90 | |

| Mitir cubic/maalintii (m3/8 saacadood) | 576-720 | |

| Tirada lebenka (blocks/ m3) | 576-720 |